Whether you require some metal roof sheeting or are in need of architectural metalwork for a large-scale project, metal fabrication gets the job done. Understanding the metal fabrication process can help you make informed decisions and set realistic expectations. From initial concept to final installation, here’s everything you need to know about how custom metal fabrication works for your project.

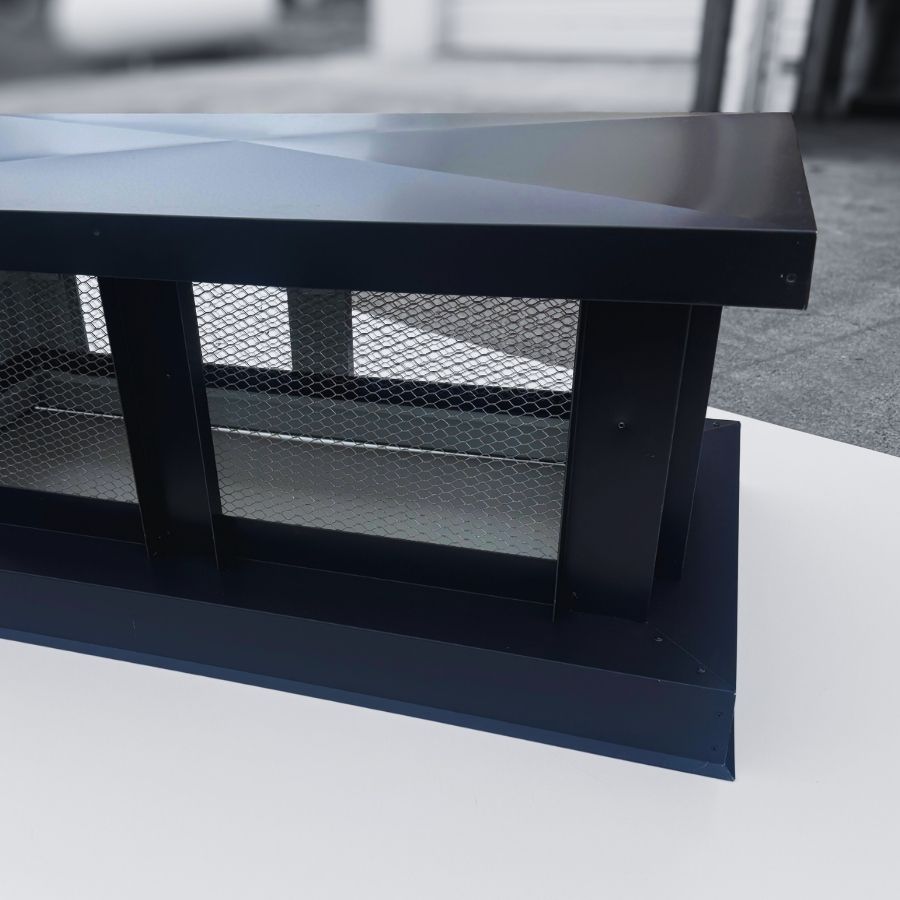

Metal fabrication is the process of cutting and assembling metal materials to create custom structures, components, and architectural elements. Unlike mass-produced metal products, custom metal fabrication allows for unique designs tailored to your specific project requirements, whether that’s railings, structural components, metal panels, flashings, or more complex architectural features.

The metal fabrication process begins with understanding your project requirements. During the initial consultation, one of our professional metal fabricators will discuss several key elements including your design preferences and aesthetic goals, functional requirements and needs, project budget and timeline, building codes and compliance requirements, and site conditions and installation challenges.

As an Oregon metal fabricator, we work with contractors to ensure the custom metalwork integrates seamlessly with the overall project design.

Next we will provide some basic shop drawings to confirm the overall design of your custom metal fabrication work. Additionally for architectural metal projects in Oregon, we take into consideration the Pacific Northwest climate when recommending materials and finishes. Various grades of Stainless steel, Galvanized Steel, Aluminum and Copper are popular choices for exterior applications due to their exceptional corrosion resistance.

Choosing the right metal is crucial for project success. Your fabricator will help you select materials based on structural requirements, corrosion resistance, aesthetic preferences, budget considerations, and maintenance expectations.

Steel is strong, versatile, and cost-effective, ideal for structural applications, railings, and gates. It requires powder coating or paint for corrosion protection in outdoor applications.

Stainless Steel offers excellent corrosion resistance and a sleek modern appearance, perfect for coastal areas, commercial kitchens, and high-end residential projects. It requires minimal maintenance and comes in various finishes including brushed, polished, and matte.

Aluminum is lightweight, naturally corrosion-resistant, and easy to work with, making it great for exterior panels, railings, and architectural accents. It’s an excellent choice for Oregon’s rainy climate.

Weathering Steel (Corten) develops a protective rust-like patina over time, offering a distinctive industrial aesthetic popular in Pacific Northwest architecture and landscape design.

Bronze and Copper provide premium aesthetic appeal with natural patina development, often used for decorative elements, handrails, and accent pieces.

Once materials are selected, your fabricator will order them from trusted suppliers, ensuring proper grades, certifications, and quantities for your project.

With materials in hand and shop drawings complete, fabrication begins. The cutting and forming phase transforms raw metal into component parts. To do this, we utilize plasma cutting tools to cut our metal to size. This method employs an electrically conductive gas to cut through thick metal quickly, ideal for structural steel and heavy-gauge materials.

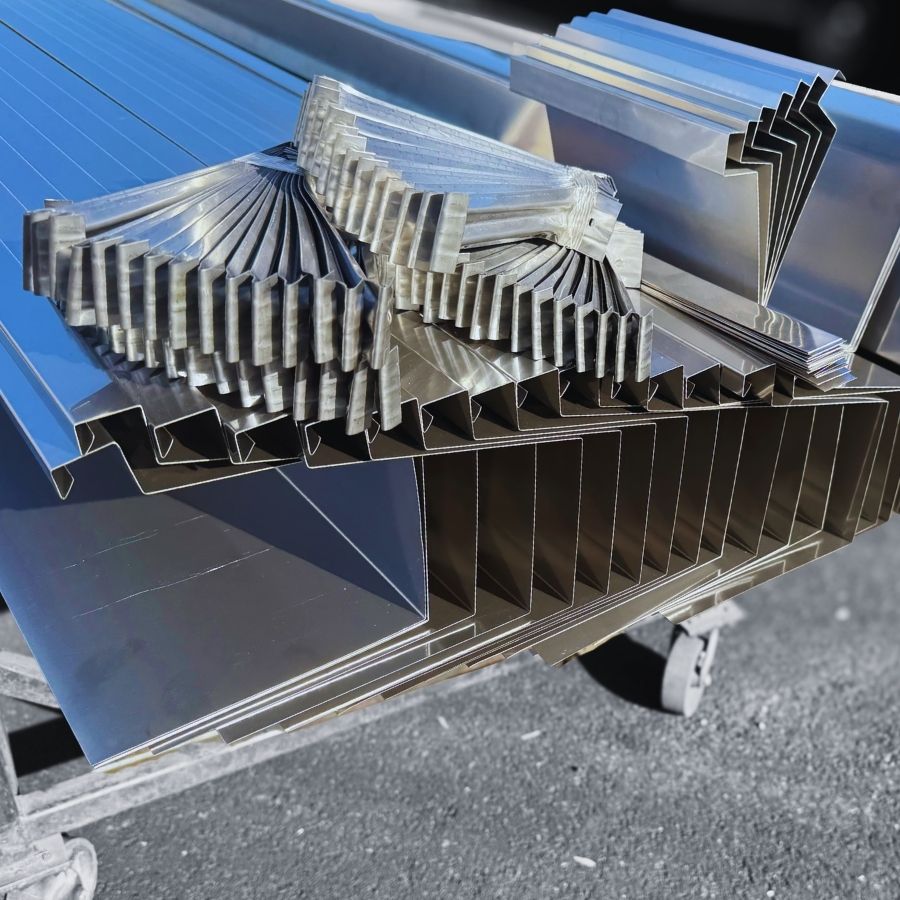

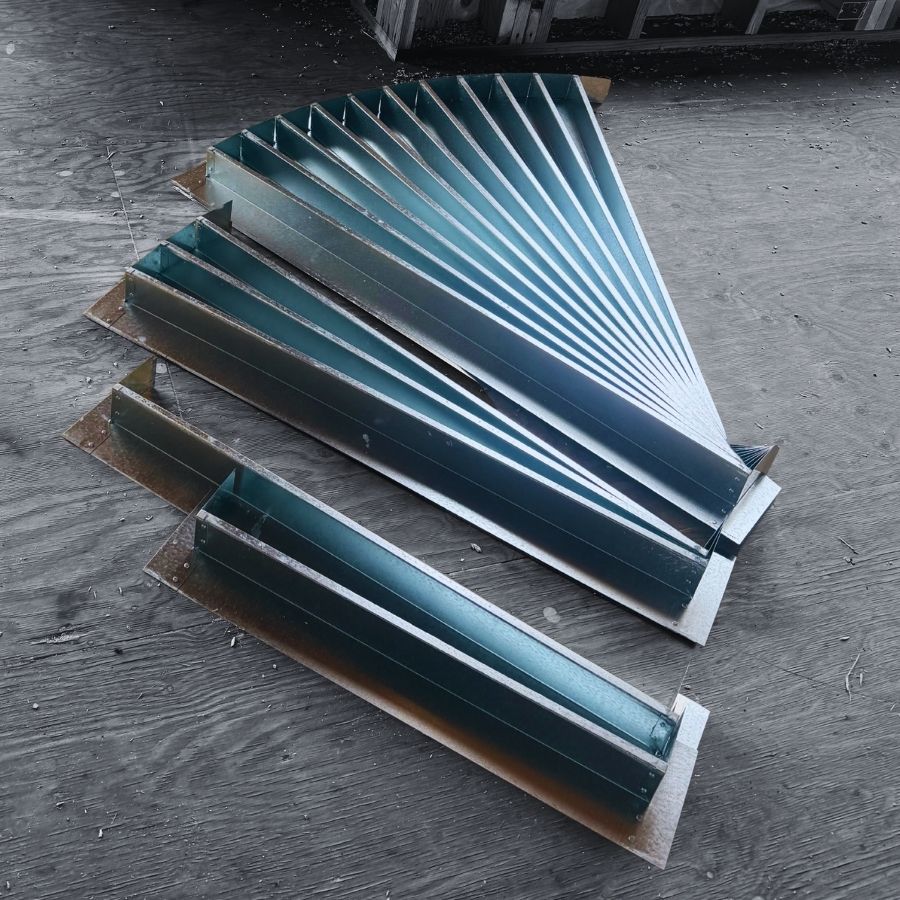

After cutting, metal pieces may need to be shaped through various forming processes. Press brakes bend sheet metal and plate to precise angles for railings, brackets, and panels. Roll forming creates curved or cylindrical shapes for columns, arches, and decorative elements. Stamping and punching create holes, patterns, and raised features in metal surfaces.

Welding joins metal components together to create the final structure. Quality welding is critical for both structural integrity and appearance. On architectural metalwork where welds are visible, fabricators may grind and polish weld seams for a seamless finish.

Assembly and Fit-Up

Large or complex metal fabrications are often assembled in sections at the shop. This allows fabricators to test fit components, ensure proper alignment, make adjustments before finishing, and prepare for efficient on-site installation.

Once fabrication and welding are complete, metal surfaces must be prepared and finished to protect against corrosion and achieve the desired appearance.

Primer Coating, or primed sheet metal refers to steel or aluminum that has been pre-treated with a base coating designed to improve its resistance to corrosion and its ability to hold paint. This preparatory layer acts as a strong foundation for any finishing work, helping to prevent rust while extending the life of the paint applied on top. It is widely used in fabrication settings where a high-quality, long-lasting, paint-ready surface is needed.

Bonderized Steel, also referred to as paintgrip, is galvanized steel that has undergone a chemical treatment process. It starts with a zinc coating applied through hot-dip galvanizing, followed by a phosphate or bonderizing treatment that improves how well paint adheres to and finishes on the surface. It’s worth noting that because of the nature of this chemical process, the material’s color can range anywhere from light gray to dark black. If the metal will be left unpainted and a consistent appearance across all pieces is important to your customer, it’s advisable to source everything from a single supplier.

Paint offers traditional protection and aesthetics with two options from our team. Kynar® (also known as Kynar 500®) is a premium paint coating made from PVDF-based resin, designed mainly to shield architectural metal surfaces — including roofs, siding, windows, and doors — from UV rays, chalking, and color fading. Made up of 70% fluoropolymer resin, it delivers exceptional durability, resistance to corrosion, and the ability to maintain its color over time, typically holding up for more than 30 years.

Galvanizing dips steel in molten zinc for superior corrosion protection, ideal for outdoor structural applications and coastal environments.

Patina Finishes use chemical treatments to create controlled oxidation on copper, bronze, or weathering steel for an aged or artistic appearance.

Brushed or Polished Finishes create directional or mirror-like surfaces on stainless steel and aluminum without additional coatings.

The choice of finish depends on the metal type, environmental exposure, aesthetic goals, and maintenance preferences.

Before leaving the fabrication shop, all metalwork undergoes thorough quality control inspection. Professional fabricators check dimensional accuracy against shop drawings, weld quality and structural integrity, finish quality and coverage, proper assembly and fit, and compliance with project specifications and building codes.

For structural components, non-destructive testing methods like ultrasonic or magnetic particle inspection may be used to verify weld quality without damaging the piece.

Once approved, fabricated metal components are carefully packaged and transported to the installation site. Large or delicate pieces require special handling including protective wrapping to prevent scratching, secure fastening to prevent shifting during transport, appropriate vehicle size and equipment for heavy items, and coordination with the installation team for delivery timing.

For projects in Portland, Eugene, Bend, or other Oregon locations, experienced metal fabricators understand local access challenges, whether that’s navigating narrow city streets, coordinating with building management, or scheduling deliveries around traffic and weather conditions.

Metal installation often needs to be coordinated with other contractors including general contractors managing the overall project schedule, concrete contractors for foundation work and anchor embedment, finish carpenters for trim and integration with wood elements, electricians if lighting is integrated into metalwork, and painters or finishers for final touches.

Good communication between your metal fabricator and other trades ensures smooth installation and a cohesive finished product.

Project timelines vary significantly based on complexity, size, and current shop workload. As a general guide, simple projects like flashings might take on to two weeks from design to installation. Medium complexity projects three weeks or more. Large or complex projects such as structural steel, extensive architectural metalwork, or multi-component installations often need four weeks or more.

Weather can impact installation schedules in Oregon, particularly for exterior work during the rainy season. Be sure to discuss realistic timelines upfront and allow for proper project planning depending on your project requirements.

The quality of your finished metalwork depends heavily on choosing the best metal fabricator for your project – choose an experienced, professional fabricator like our team! But in general, look for proven experience with projects similar to yours, certified welders, quality control processes, proper licensing and insurance, positive customer reviews and portfolio examples, and clear communication throughout the process.

Proper maintenance extends the life and appearance of your custom metalwork. Most finishes require only periodic cleaning with mild soap and water. Inspect for damage, loose fasteners, or finish degradation annually. Touch up scratches or chips promptly to prevent corrosion. For moving parts like gates, apply appropriate lubricant as needed.

In Oregon’s climate, pay particular attention to areas where water can collect or where dissimilar metals meet, as these are most vulnerable to corrosion.

We hope that understanding the metal fabrication process helps you appreciate the craftsmanship behind custom metalwork and sets appropriate expectations for your project. From initial design concept through final installation, each step requires skill, precision, and attention to detail – working with an experienced metal fabricator ensures quality results that will last for decades.

Ready to start your custom metal fabrication project? Contact our team at West Coast Metal Fabrication, your Oregon metal fabricator, to discuss your vision and receive a detailed quote. The journey from design to installation begins with a single conversation about what’s possible.

Phone

(458) 253-9427

Address

West Coast Metal Fab

36845 Crackerneck Dr.

Scio, OR 97374